A Truckers Guide to Loading Dock Delays and Downtime

Any truck driver who has been around the block a time or two is well aware that spending time waiting at a shipper or receiver’s dock is just part of the job.

Drivers also know that delays and extended trucker downtimes can happen, and when they do, they can sometimes derail a tight schedule, cut into drive time, and even start to impact the driver’s paycheck. At the end of the day, there's a good chance the truck driver cannot do anything about delays like this.

The best thing truckers can do is be prepared and have a strong understanding of best practices when it comes to loading dock etiquette and using their downtime wisely.

Below, we will dive into some of the causes of loading dock delays, how they can affect truckers, and what drivers can do to turn that downtime into something useful.

Why Loading Dock Delays Happen

Before we get into what truckers do to make the most of downtime at loading docks, we first need to understand loading dock wait times and potential delays.

When talking about delays, the biggest culprits are simply overbooked docks and short-staffed crews. Warehouses can sometimes schedule more trucks than they can handle, leading to a backlog and waiting truckers.

One industry study found that 10% of drivers have experienced over six hours of downtime at loading docks in some cases, often because the yard was jammed. While that is only 1 out of 10 drivers, six hours can have a huge impact on a trucker's schedule if you are unlucky enough to hit such a delay.

Then there’s the labor side. Many facilities in today's world are short on dock workers, which slows things down. Disorganized loading processes, late shipments, or broken loading dock parts and equipment only make it worse. First-come, first-served systems can also punish drivers who show up even slightly late.

Surveys back this up: Trucker Tools reported 60% of carriers wait more than two hours per load, and according to DAT, 63% of drivers regularly wait over three hours, showing that these delays are more common than not.

The Toll on Schedules and Paychecks

Every minute spent parked at a dock eats into a driver’s legal Hours of Service (HOS).

According to ATRI, 83% of drivers run out of allowable hours because of detention time. That can often lead to them missing their next pickup or delivery and losing miles for the day.

Financially, it gets even tougher.

While carriers can bill for downtime or detention, most drivers never see that money. A 2021 survey said 79% of drivers rarely or never receive detention pay, even when waiting over two hours. The DOT’s Office of Inspector General estimated that detention robs the industry of $1.1–$1.3 billion annually. That’s about $1,300 off the average driver’s annual income.

Long waits can also increase fatigue in some cases. Research shows that just a 15-minute increase in detention potentially raises crash risk by over 6%, meaning delays aren’t just annoying, but can be dangerous.

Logging Waiting Time: What Counts and What Doesn’t

According to FMCSA, any time spent loading, unloading, or attending the truck is “on-duty, not driving.” That includes trucker downtime at the dock unless you’re officially relieved of work.

With that being said, if you climb into the sleeper and aren’t doing any work, that can count as “sleeper berth” or “off-duty.”

That distinction matters, as off-duty time doesn’t eat into your driving window.

You can also use the sleeper berth split (8 hours in the bunk and 2 off-duty elsewhere, or vice versa) to reset your HOS clock. Many drivers do this in an attempt to strategically reset their hours.

In short, unless you’re sleeping or completely off the clock, the downtime you spend at the dock likely counts against your workday, so it's important to make good use of it.

How Drivers Use Their Downtime

Now that we have a firm grasp on dock delays and some of the concerns around driver hours at the dock, let's cover how tuckers can put their downtime to the best possible use.

Sleep and Rest

[Photo courtesy of Sleeping Dog Mattress]

A nap in the sleeper can be the most productive thing you do during a delay. It helps you stay alert later and can reset your HOS.

There are a variety of different types of trucks that you’ll typically see at a loading dock, some being for short-distance loads and some for longer hauls. Most long-haul truckers have a sleeper cab, where they can rest on their sleeper sized mattress during the waiting period, especially for longer durations of downtime.

Now, even if the trucker doesn’t have a sleeper cab, most truckers have adapted to being able to get some quick shuteye in the driver's seat, ultimately giving them the little bit of rest they could really benefit from before the next leg of their drive.

Entertainment and Hobbies

When the wait isn’t long enough to sleep, truckers will often turn to a variety of short-term entertainment, such as books, streaming, music, podcasts, or journaling. Some drivers have reported even enjoying short walks to loosen up their legs before driving again.

Some truckers have even said they aren't opposed to taking a quick Uber ride to explore nearby towns if they are looking at one of those 6-hour wait times!

Exercise

As we hinted towards before when we mentioned taking quick walks, a lot of drivers use their downtime to get in some much-needed exercise after a day on the road.

Sitting in a driver's seat for extended periods of time takes a toll. Stretching, walking laps near the truck, or using resistance bands and other simple exercise equipment can significantly relieve stiffness and improve the driver's overall mood.

Even a few push-ups on the side of the trailer make all the difference. There is a wide range of truck driver-related health issues that can be avoided through simple exercise and staying active whenever possible.

Staying Connected

Just as truckers do everything they can to make their sleeper cabs seem like a home away from home, staying connected with family is just as important for morale.

Calls home, texting friends, or chatting in online forums help pass the time and stay grounded after long trips by yourself. Driving can be isolating, so trucker downtime often turns into social time, and studies show staying connected with family helps with trucker morale.

Work Tasks and Maintenance

Just as any trucker knows, delays are a very real possibility, and they also know the trucking profession comes with a lot of managerial work beyond just driving.

Many will use the delay to organize receipts, plan their route, or inspect their rig. A quick check on tires or fluids could catch an issue before it ruins their next haul and racks up unexpected expenses.

Since FMCSA considers this on-duty work, it’s also a smart way to stay productive.

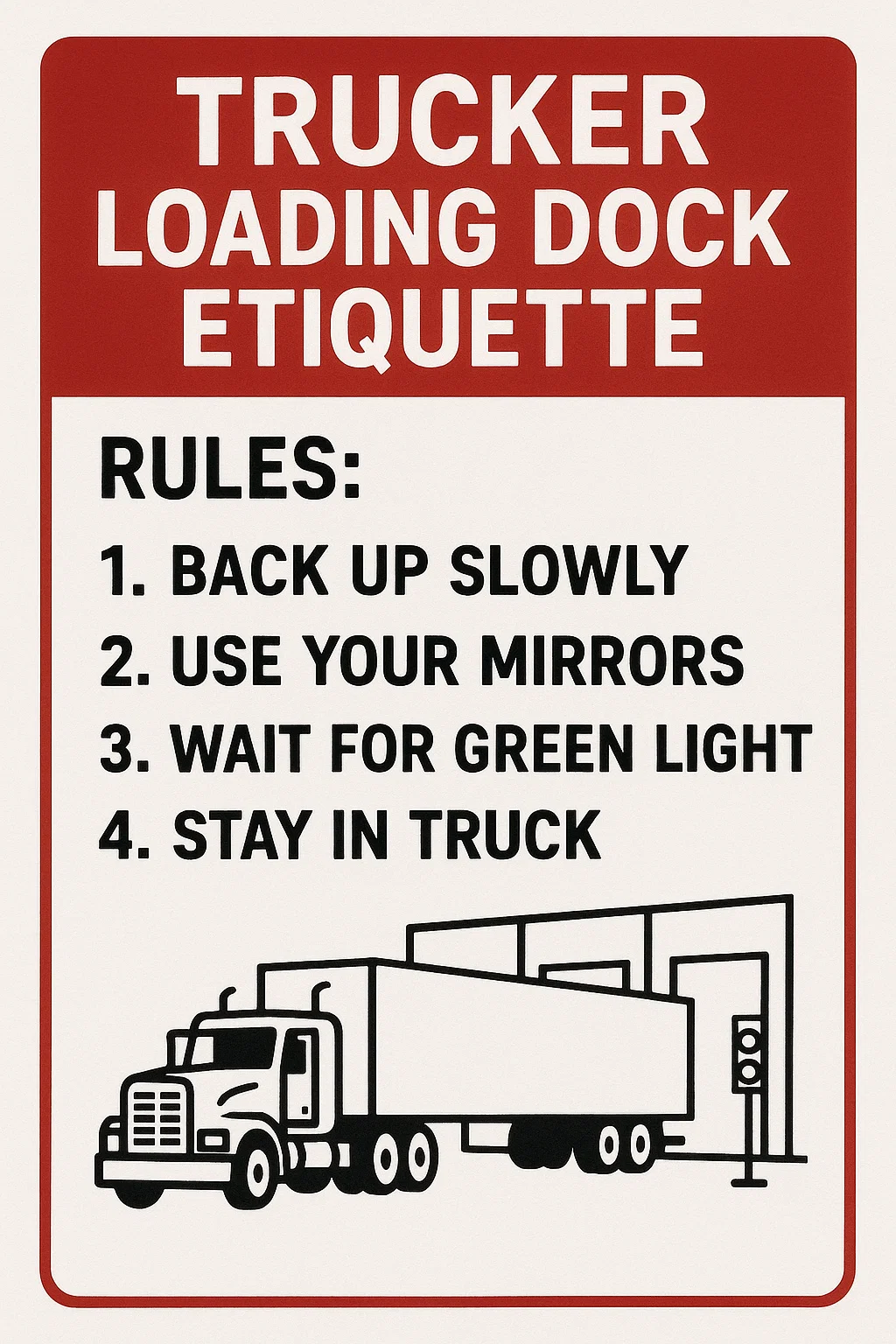

Dock Etiquette 101

At the end of the day, you are sharing the loading dock and surrounding parking space with other drivers who are all trying to accomplish the same goal as you.

Load up and head out as quickly as possible.

So, just as with any shared space in a profession, there are generally accepted rules and expectations when it comes to dock etiquette.

Communicate clearly

Let the dispatch or dock staff know as soon as you arrive. It's also important to answer check-ins quickly so that the loading dock crew can turn over loads as quickly as possible, improving overall loading dock efficiency.

Disappearing without notice and missing your call will not only push back your timeline, but will also cause a headache for the loading dock crew, who will quickly move to the next driver without hesitation.

Just remember, you’re there to get your truck loaded and get out, so don’t get over-distracted or sleep through your call.

Follow the rules

Most loading docks have some of the same base rules, with some exceptions. One of those basic rules is to park where you’re supposed to, even if it's inconvenient.

While it might seem obvious, you also need to respect line order. Nothing will cause bad blood between drivers like one cutting the other off or thinking their load is more important.

Lastly, know whether the facility uses appointment times or FCFS. Planning ahead can be extremely useful if you have a set pickup time, and knowing if a dock is FCFS might have a huge impact on when you plan on leaving and arriving at the loading dock.

Wear the gear

If PPE is required (vest, boots, hard hat), wear it. Don’t be that guy who thinks he is the exception, because you aren’t.

Even if PPE is not mandatory, dock workers are quite likely to appreciate the extra care for safety, and there is no drawback to an extra layer of protection.

Stay close, but not in the way

Don’t wander the warehouse or pester the crew working the docks. If it's FCFS, just know they are doing everything they can to get you in and get you out as quickly as possible with minimum downtime for truckers.

If you must be out in the warehouse or loading dock, just be aware of forklifts and other heavy equipment commonly used at loading docks, as well as other drivers coming and going.

Be respectful

Last but not least, be a good person. The people working the docks are juggling dozens of trucks and loads, which can get quite stressful. Being the driver who is easy to work with and doesn’t cause a commotion can go a long way, especially if you’re picking up regular loads at the dock.

A good attitude can make your wait easier and possibly shorter. At the end of the day, loading dock maintenance issues happen more than you think, so have patience, the workers will appreciate it. There is no negative to earning a good reputation at the loading dock.

Be Prepared: Tips That Pay Off

Now that you have a 10,000-foot understanding of how to carry yourself and act at the loading dock, let's get into some of the tips and tricks that can help you get in and out quicker, as well as make the most of your time while you wait.

Keep paperwork organized

Have your BOL, seal number, and instructions ready to go. A simple folder or clipboard can save time for everyone.

Use chocks and lights

Chock your wheels, set your brake, and use hazard lights if waiting in the dark. It doesn’t take much effort at all and is safer for everyone.

Clean up after yourself

Don’t be the driver to leave trash or spills behind. A clean truck area leaves a better impression on dock staff, and a happy dock staff means happy drivers.

Come supplied

While some loading docks might have a gas station or corner store nearby, it's best to have your own downtime supply, such as snacks, water, and weather gear on hand. Even these small things can make a huge difference during long delays and inclement weather.

Manage your clock

Again, depending on whether you have a loading time or if the dock is FCFS, aim to arrive just early enough to avoid being late, but not so early that you block access or create confusion. The best thing you can do for loading dock workers is to avoid causing unnecessary heavy traffic, which can lead to further delays.

Most experienced drivers report shooting for about 30 minutes before their loading time, which seems to be the sweet spot because if the dock is ahead of schedule, or if they are delayed, you won’t take up too much space for too long.

Master The Loading Dock

While yes, dock delays are frustrating, they don’t have to be completely wasted time.

Trucker downtime at loading docks should not be viewed as an overall loss for the driver, but rather a quick break to gather yourself, make sure your truck is ready for its next leg of the journey, and even catch up on some Zs before hitting the road.

Just remember, relationships are everything in this business, and you’d much rather be a truck that loading dock workers are relieved to see pull in as opposed to being “that guy”.

Essential Strategies to Minimize Trucker Downtime and Maximize Profit

Causes and Effects of Downtime

-

Downtime can significantly impact the profit and loss reports of truck drivers and owner operators, resulting in lost profits and increased expenses.

-

Accidents and equipment breakdowns are common causes of downtime, and truck drivers may need to file a claim with their insurance company to recover losses.

-

Regular maintenance is crucial to prevent downtime and minimize the likelihood of accidents and repairs.

-

Owner operators who own their trucks must be aware of the potential causes of downtime and take steps to mitigate its effects.

Preventing Downtime for Owner Operators

-

Owner operators can prevent downtime by keeping track of their vehicle’s maintenance schedule and addressing any issues promptly.

-

Having a replacement truck or rental option available can help minimize downtime in case of an accident or breakdown.

-

Owner operators should also keep detailed records of their income and expenses, including tax returns and profit and loss reports, to demonstrate their losses in case of a claim.

-

By being proactive and prepared, owner operators can reduce the risk of unpleasant surprises and minimize downtime.

Managing Downtime in the Trucking Business

-

Effective management of downtime is critical to the success of the trucking business, as it can help minimize lost profits and reduce expenses.

-

Trucking companies can manage downtime by implementing strategies such as regular maintenance, driver training, and having a contingency plan in place.

-

Downtime coverage can also provide reimbursement for expenses, helping truckers to get back on the road quickly.

-

By managing downtime effectively, trucking companies can maximize profit and stay competitive in the industry.

Optimizing Profit for Truck Drivers

-

Truck drivers can optimize their profit by minimizing downtime and maximizing their time on the road.

-

Having a good understanding of their expenses, including fuel, maintenance, and bills, can help truck drivers make informed decisions about their business.

-

Truck drivers should also be aware of the importance of downtime coverage and have a plan in place in case of an accident or breakdown.

-

By being proactive and taking steps to minimize downtime, truck drivers can increase their profit and achieve financial success in the trucking industry.

Essential Strategies to Minimize Trucker Downtime and Maximize Profit

Causes and Effects of Downtime

-

Downtime can significantly impact the profit and loss reports of truck drivers and owner operators, resulting in no being paid and increased expenses.

-

Accidents and equipment breakdowns are common causes of downtime, and truck drivers may need to file a claim with their insurance company to recover losses.

-

Regular maintenance is crucial to prevent downtime and minimize the likelihood of accidents and repairs.

-

Owner operators who own their trucks must be aware of the potential causes of downtime and take steps to mitigate its effects.

Preventing Downtime for Owner Operators

-

Owner operators can prevent downtime by keeping track of their vehicle’s maintenance schedule and addressing any issues promptly.

-

Having a replacement truck or rental option available can help minimize downtime in case of an accident or breakdown.

-

Owner operators should also keep detailed records of their income and expenses, including tax returns and profit and loss reports, to demonstrate their losses in case of a claim.

-

By being proactive and prepared, owner operators can reduce the risk of unpleasant surprises and minimize downtime.

Managing Downtime in the Trucking Business

-

Effective management of downtime is critical to the success of the trucking business, as it can help minimize lost profits and reduce expenses.

-

Trucking companies can manage downtime by implementing strategies such as regular maintenance, driver training, and having a contingency plan in place.

-

Downtime coverage can also provide reimbursement for lost income and expenses, helping truckers to get back on the road quickly.

-

By managing downtime effectively, trucking companies can maximize profit and stay competitive in the industry.

Optimizing Profit for Truck Drivers

-

Truck drivers can optimize their profit by minimizing downtime and maximizing their time on the road.

-

Having a good understanding of their expenses, including fuel, maintenance, and bills, can help truck drivers make informed decisions about their business.

-

Truck drivers should also be aware of the importance of downtime coverage and have a plan in place in case of an accident or breakdown.

-

By being proactive and taking steps to minimize downtime, truck drivers can increase their profit and achieve financial success in the trucking industry.

Essential Strategies to Minimize Trucker Downtime and Maximize Profit

Causes and Effects of Downtime

-

Downtime can significantly impact the profit and loss reports of truck drivers and owner operators, resulting in lost profits and increased expenses.

-

Accidents and equipment breakdowns are common causes of downtime, and truck drivers may need to file a claim with their insurance company to recover losses.

-

Regular maintenance is crucial to prevent downtime and minimize the likelihood of accidents and repairs.

-

Owner operators who own their trucks must be aware of the potential causes of downtime and take steps to mitigate its effects.

Preventing Downtime for Owner Operators

-

Owner operators can prevent downtime by keeping track of their vehicle’s maintenance schedule and addressing any issues promptly.

-

Having a replacement truck or rental option available can help minimize downtime in case of an accident or breakdown.

-

Owner operators should also keep detailed records of their income and expenses, including tax returns and profit and loss reports, to demonstrate their losses in case of a claim.

-

By being proactive and prepared, owner operators can reduce the risk of unpleasant surprises and minimize downtime.

Managing Downtime in the Trucking Business

-

Effective management of downtime is critical to the success of the trucking business, as it can help minimize lost profits and reduce expenses.

-

Trucking companies can manage downtime by implementing strategies such as regular maintenance, driver training, and having a contingency plan in place.

-

Downtime coverage can also provide reimbursement for lost income and expenses, helping truckers to get back on the road quickly.

-

By managing downtime effectively, trucking companies can maximize profit and stay competitive in the industry.

Optimizing Profit for Truck Drivers

-

Truck drivers can optimize their profit by minimizing downtime and maximizing their time on the road.

-

Having a good understanding of their expenses, including fuel, maintenance, and bills, can help truck drivers make informed decisions about their business.

-

Truck drivers should also be aware of the importance of downtime coverage and have a plan in place in case of an accident or breakdown.

-

By being proactive and taking steps to minimize downtime, truck drivers can increase their profit and achieve financial success in the trucking industry.

Essential Strategies to Minimize Trucker Downtime and Maximize Profit

Causes and Effects of Downtime

-

Downtime can significantly impact the profit and loss reports of truck drivers and owner operators, resulting in lost profits and increased expenses.

-

Accidents and equipment breakdowns are common causes of downtime, and truck drivers may need to file a claim with their insurance company to recover losses.

-

Regular maintenance is crucial to prevent downtime and minimize the likelihood of accidents and repairs.

-

Owner operators who own their trucks must be aware of the potential causes of downtime and take steps to mitigate its effects.

Preventing Downtime for Owner Operators

-

Owner operators can prevent downtime by keeping track of their vehicle’s maintenance schedule and addressing any issues promptly.

-

Having a replacement truck or rental option available can help minimize downtime in case of an accident or breakdown.

-

Owner operators should also keep detailed records of their income and expenses, including tax returns and profit and loss reports, to demonstrate their losses in case of a claim.

-

By being proactive and prepared, owner operators can reduce the risk of unpleasant surprises and minimize downtime.

Managing Downtime in the Trucking Business

-

Effective management of downtime is critical to the success of the trucking business, as it can help minimize lost profits and reduce expenses.

-

Trucking companies can manage downtime by implementing strategies such as regular maintenance, driver training, and having a contingency plan in place.

-

Downtime coverage can also provide reimbursement for lost income and expenses, helping truckers to get back on the road quickly.

-

By managing downtime effectively, trucking companies can maximize profit and stay competitive in the industry.

Optimizing Profit for Truck Drivers

-

Truck drivers can optimize their profit by minimizing downtime and maximizing their time on the road.

-

Having a good understanding of their expenses, including fuel, maintenance, and bills, can help truck drivers make informed decisions about their business.

-

Truck drivers should also be aware of the importance of downtime coverage and have a plan in place in case of an accident or breakdown.

-

By being proactive and taking steps to minimize downtime, truck drivers can increase their profit and achieve financial success in the trucking industry.

Owner, Parts Brite

My background is in Electrical and Software Engineering, but since I started PartsBrite.com in 2016, I've focused on everything related to docks.

My team and I are here to help those looking to repair or replace their dock levelers, bumpers, door, and door lights.

1-855-PartsBrite | partsbrite.com | paul@partsbrite.com

Leave a comment