4 Measurements You Need to Measure a Loading Dock Spring: The Essential Guide

Loading dock springs are an essential component of dock levelers, ensuring smooth and efficient operation during the loading and unloading goods. However, their importance is often overlooked, leading to potential safety hazards and costly repairs. In this blog post, we will delve into the world of loading dock springs, exploring their types, common signs of wear, and the crucial steps on “how do I measure a loading dock spring” for optimal performance. So, let us embark on this journey to ensure the longevity and safety of your loading dock equipment.

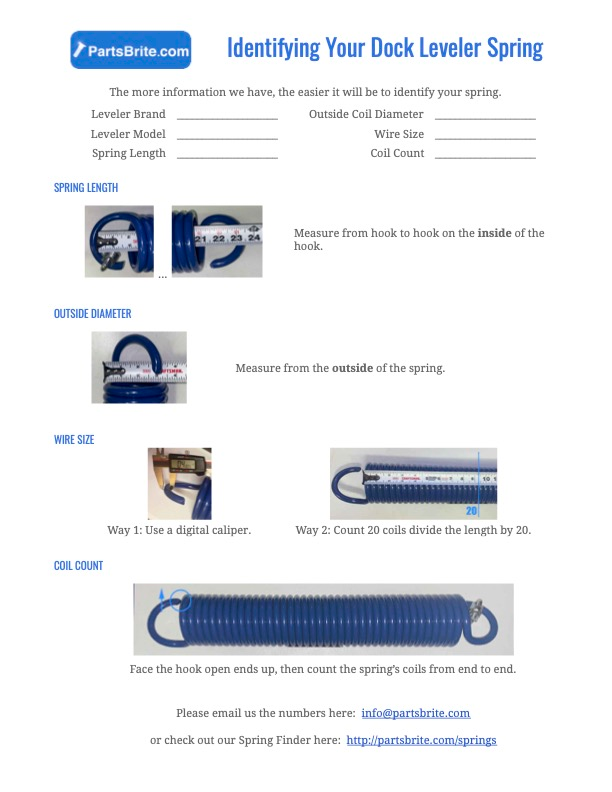

Short Cut

-

Picture guide to help specify your spring. Download this PDF.

-

If you know your measurements check out our leveler spring finder here.

Short Summary

-

Understanding loading dock springs and common signs of wear or damage is essential to ensure safe operations.

-

Measurement tools, such as a measuring tape/ruler, calipers, and spring rate tester, can be used for accurate measurements.

-

Regular inspection & maintenance, including lubrication & cleaning, is key to detecting signs of wear or tear for timely replacement.

Understanding Loading Dock Springs

The success of any loading dock operation relies heavily on the proper functioning of dock levelers. These devices play a pivotal role in bridging the gap between the loading dock and the trailer, ensuring a seamless flow of goods between the two. While all loading dock levelers use springs, at the heart of a mechanical leveler lies the main extension springs, which provide the necessary tension to maintain the dock leveler lip in position and cushion the impact during loading and unloading operations.

Without adequate maintenance, these springs can wear down or become damaged, leading to decreased performance and potential safety hazards.

Types of Springs Used in Dock Levelers

Loading dock levelers, including mechanical dock levelers, employ a variety of springs, such as the main extension spring, each designed to cater to specific requirements. Torsion, extension, and compression springs are the most common types of springs used in dock levelers.

Torsion springs function by twisting or rotating around their axis, providing a torque or rotational force. Extension springs, on the other hand, extend when a force is applied, generating a linear force. Lastly, compression springs operate by compressing or squeezing when a force is applied, also offering a linear force.

Understanding the different types of springs and their functionality is crucial for proper maintenance and ensuring the longevity of your dock leveler. For a fuller description of types of leveler springs, check out this blog post.

Common Signs of Spring Wear or Damage

Springs, like any other mechanical component, are susceptible to wear and damage over time. Regular inspection is essential to identify and address any issues before they escalate and compromise the safety and efficiency of your loading dock operations. Common signs of wear or damage to loading dock springs include:

-

Rust

-

Deformation

-

Decreased elasticity

-

Breaks in the spring

If you notice any of these signs, it is important to take immediate action to repair or replace the springs to ensure the continued safe and smooth operation of your loading dock.

It is crucial to address these signs of wear or damage promptly, as ignoring them can lead to equipment malfunction, increased downtime, and potential safety hazards. By conducting regular inspections and maintenance, you can keep your loading dock springs in optimal condition and prolong the life of your dock leveler.

Measuring Your Loading Dock Spring

Now that we understand the importance of loading dock springs and how to identify signs of wear or damage let’s dive into the process of measuring them. Measuring a loading dock spring accurately is essential for selecting the right replacement and ensuring the proper functioning of your dock leveler.

In the following subsections, we will discuss the tools required for measuring, as well as the steps involved in measuring the length, diameter, and spring rate of a loading dock spring.

Tools Required for Measuring

To measure a loading dock spring accurately, you’ll need a few essential tools.

-

A measuring tape or ruler to measure the overall length of the spring from the inside, hook-to-hook

-

Calipers to measure the diameter of the spring at the end of the coil

Having the right material handling equipment at your disposal not only ensures accurate measurements but also makes the process more efficient and straightforward. With these tools in hand, you’ll be well-equipped to measure and assess your loading dock springs with precision.

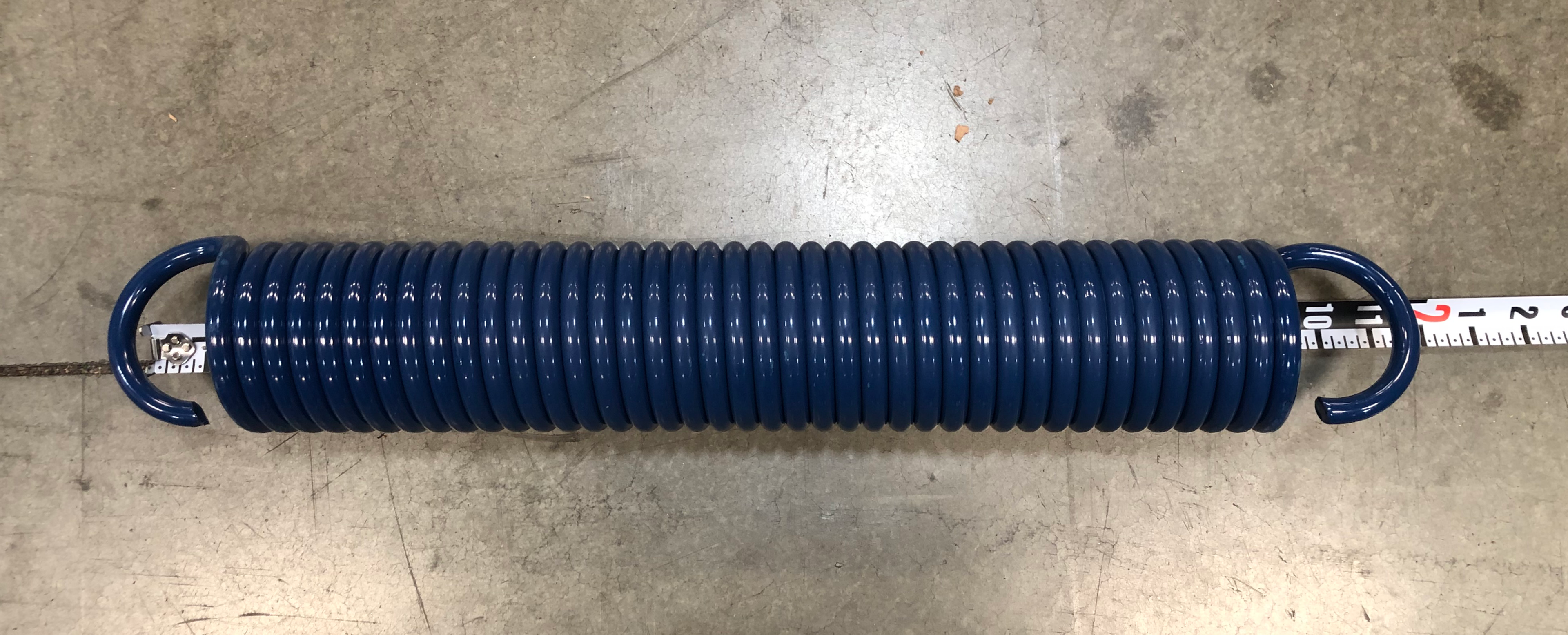

Measuring Length and Diameter

To measure the length of a loading dock spring, follow these steps:

-

Use a measuring tape or ruler to measure from the initial coil on one end to the terminal coil on the opposite end.

-

Make sure to take accurate measurements of the spring’s length.

-

These measurements are essential for selecting the proper replacement and ensuring optimal performance.

Next, utilize calipers to measure the diameter of the loading dock spring at the center of the coil and at the end of the coil. The diameter is a crucial factor in determining the spring’s load capacity and compatibility with your dock leveler.

By taking precise measurements of both the length and diameter of your loading dock spring, you can ensure a proper fit and seamless operation of your dock leveler.

Choosing the Right Replacement Spring

Selecting the right replacement spring for your loading dock leveler is crucial for maintaining safe and efficient operation. In this section, we will discuss:

-

The importance of checking the owner’s manual for spring specifications

-

Comparing the specifications of the existing spring with potential replacements

-

The option of custom springs for unique applications.

It is important to check the owner’s manual for the exact spring specifications for your vehicle.

Checking the Owner's Manual

The owner’s manual for your loading dock leveler is an invaluable resource when selecting a replacement spring. It contains information on the operation and troubleshooting of the dock leveler, as well as specifications and installation instructions. Consulting the owner’s manual to verify spring specifications and compatibility is essential to guarantee that the spring is the appropriate size and type for the dock leveler. This will ensure that the spring has the capacity to support the dock leveler’s weight and that it will operate correctly.

If the owner’s manual does not provide the necessary information, it is advisable to contact a qualified technician or the dock leveler manufacturer for assistance. They can help guide you in selecting the proper replacement spring and ensuring a seamless installation process.

Comparing Specifications with Existing Spring

To ensure a proper fit and compatibility, it’s essential to compare the specifications of your existing spring with potential replacements. This includes assessing the length, diameter, and spring rate of the spring. By cross-referencing these measurements with the specifications outlined in the owner’s manual, you can guarantee a suitable match that will provide optimal performance and safety for your dock leveler.

Selecting the right replacement spring is critical for the longevity and efficient operation of your loading dock leveler. By taking the time to compare the specifications of the existing spring with potential replacements, you can avoid costly mistakes and ensure a seamless transition.

Custom Springs for Unique Applications

In some cases, standard springs may not be suitable for your specific loading dock application. Custom springs are tailored solutions designed to meet the needs of unique or specialized loading dock applications. These springs offer exclusive benefits, such as decreased solid height, lateral stability, and the capacity to withstand the motion of another component.

When selecting custom springs for unique applications, it is imperative to consider the following factors:

-

Application requirements

-

Environment

-

Load requirements

-

Desired spring rate

By carefully evaluating these factors, you can ensure the custom spring is perfectly suited to your application, enhancing performance, optimizing efficiency, and decreasing costs.

Installing and Adjusting the New Loading Dock Spring

Once you have selected the right replacement spring, the next step is to install and adjust it safely and effectively. In this section, we will cover the following:

-

Safety precautions to follow during the installation process

-

Step-by-step guide for installing a new loading dock spring

-

How to adjust spring tension to ensure optimal performance and safety

Safety is paramount when installing a new loading dock spring. Make sure to wear protective gear.

Safety Precautions During Installation

Safety is of utmost importance when installing a new loading dock spring. Before beginning the installation process, ensure you are following these safety precautions:

-

Wear protective gear such as gloves, safety glasses, and a hard hat.

-

Adhere to the manufacturer’s instructions and employ suitable tools.

-

Take necessary precautions to prevent injury or damage to yourself, other people, and the loading dock spring.

By carefully following these safety precautions and any additional resources for safety information, such as the manufacturer’s instructions, safety manuals, and online safety resources, you can ensure a smooth and secure installation process.

Step-by-Step Installation Guide

To install a new loading dock spring, follow these steps: First, ensure the spring is correctly aligned and firmly fastened. Next, consult the owner’s manual to ensure the accuracy of the spring’s specifications, including length and diameter.

Once the new spring is installed, follow these steps to ensure a proper installation.

-

Compare the specifications of the existing spring with the new spring by measuring the length and diameter of the existing spring.

-

Cross-reference the measurements with the specifications outlined in the owner’s manual.

-

By following this step-by-step guide, you can guarantee a proper installation that will provide optimal performance and safety for your loading dock leveler.

Adjusting Spring Tension

After installing the new loading dock spring, it is essential to adjust the tension to ensure optimal performance and safety. To adjust the tension, follow these steps:

-

Use a wrench to turn the spring adjustment nut clockwise for a higher setting or counterclockwise for a lower setting.

-

Test the tension by operating the dock leveler and observing its performance.

-

Make further adjustments as needed until the tension is properly set.

Proper tension adjustment is crucial for the smooth operation of your dock leveler, which includes its tread plate, and the prevention of potential safety hazards, such as a malfunctioning restraining device.

By accurately adjusting the spring tension, you can maintain the optimal performance and safety of your loading dock operations, ensuring a seamless loading and unloading process for your personnel and equipment.

Maintaining Your Loading Dock Springs

Proper maintenance of your loading dock springs is essential to prolong their lifespan and ensure safe operation. In this section, we will discuss the importance of regular inspection and maintenance.

We recommend lubrication and cleaning to keep your springs in good condition. Guidelines on when to replace a loading dock spring should also be followed.

Regular Inspection and Maintenance

Regular inspection and maintenance of your loading dock springs are critical to preventing wear and damage, ensuring safe operation, and prolonging the life of your equipment. It is recommended to inspect dock leveler springs at least once a month. If you notice any signs of wear or damage, such as rust, fraying, or breaks in the spring, it is essential to replace the spring promptly to avoid equipment malfunction and potential safety hazards.

By conducting regular inspections and maintenance, you can keep your loading dock springs in optimal condition, ensuring the longevity and safety of your dock leveler.

Lubrication and Cleaning

Lubrication and cleaning are essential to prevent rust and debris buildup in your loading dock springs, which can lead to premature wear and reduced efficiency. For optimal lubrication and cleaning, use penetrating oil on the hinges, pins, springs, and any areas prone to rust. It is advised to lubricate all grease fittings every 90 days.

By regularly lubricating and cleaning your loading dock springs, you can maintain their optimal performance and prolong their lifespan, ensuring the continued smooth operation of your loading dock leveler.

When to Replace a Loading Dock Spring

Indications that a loading dock spring needs to be replaced include the following:

-

Visible wear and tear

-

Rust

-

Fraying

-

Breaks in the spring

-

Decreased performance

-

The dock leveler is not operating correctly

Keeping an eye out for these signs and replacing the spring in a timely manner is crucial for maintaining the safety and efficiency of your loading dock operations.

Regular maintenance and inspections of the loading dock spring are essential for ensuring that it is in good working condition, especially in areas with multiple loading docks and a wide working range.

Summary

In conclusion, loading dock springs play a vital role in ensuring the smooth operation of dock levelers and the safety of loading dock personnel. By understanding the types of springs, recognizing signs of wear or damage, accurately measuring and selecting the right replacement, and adhering to proper installation and maintenance procedures, you can optimize the performance and longevity of your loading dock equipment. Don’t let a worn or damaged spring compromise the safety and efficiency of your loading dock operations – invest in regular inspections, maintenance, and timely replacements to keep your loading dock running smoothly.

Source for Loading Dock Springs

PartsBrite.com has lots of dock leveler springs in stock.

We have a considerable number of springs, too many more to show. Give us a call at 855-7278727 or email us at info@partsbrite.com.

Frequently Asked Questions

How do you measure dock levelers?

To measure dock levelers, measure the width from curb angle to curb angle and the length from the front opening on the dock wall to the back of the pit.

What is the size of a loading dock?

The size of a loading dock typically ranges from 42-56 inches high to accommodate different truck bed sizes of 40-60 inches.

A dock plate or leveler is used to allow forklifts to enter and exit trucks.

What is the standard height of a loading dock?

The standard dock height within North American facilities is 48 in., though this can range from 48-55 in.

What types of springs are commonly used in loading docks?

Torsion, extension, and compression springs are the most commonly used types of springs in loading docks.

These springs are used to absorb shock, reduce vibration, and provide support for heavy loads. They are also used to help maintain the alignment of the dock and its components. They are designed for their purpose.

How often should dock leveler springs be inspected?

It is recommended to inspect dock leveler springs at least once a month for optimal performance.

Owner, Parts Brite

My background is in Electrical and Software Engineering, but since I started PartsBrite.com in 2016, I've focused on everything related to docks.

My team and I are here to help those looking to repair or replace their dock levelers, bumpers, door, and door lights.

1-855-PartsBrite | partsbrite.com | paul@partsbrite.com

Leave a comment